Welcome to Guangzhou Tongsen Electronic Technology Co., LTD. Website!

Main business scope

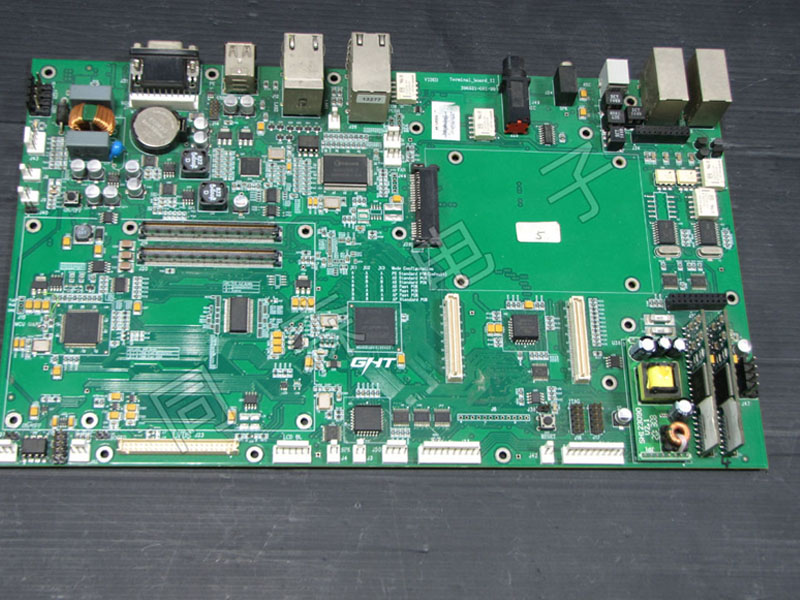

PCBA one-stop service

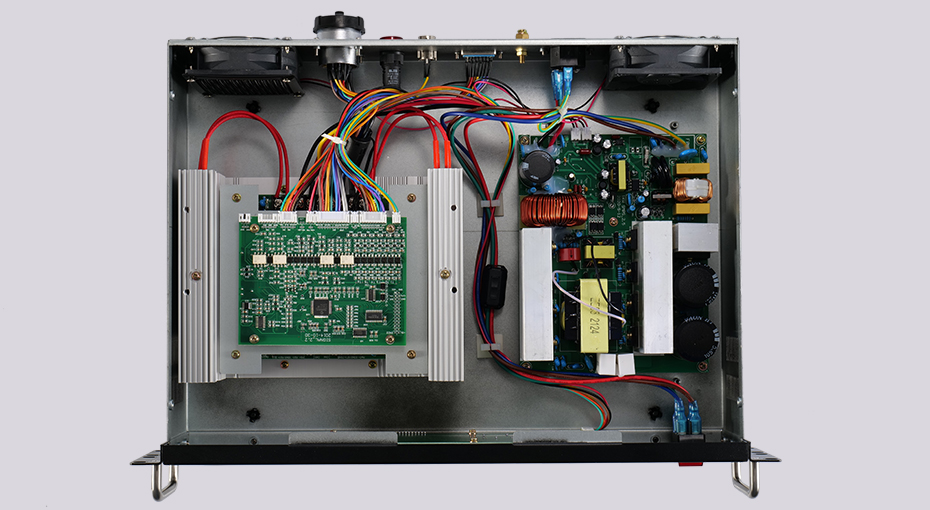

A full range of services from PCB production, component procurement to SMT patch, DIP plug-in processing and testing. All components are guaranteed to be genuine.

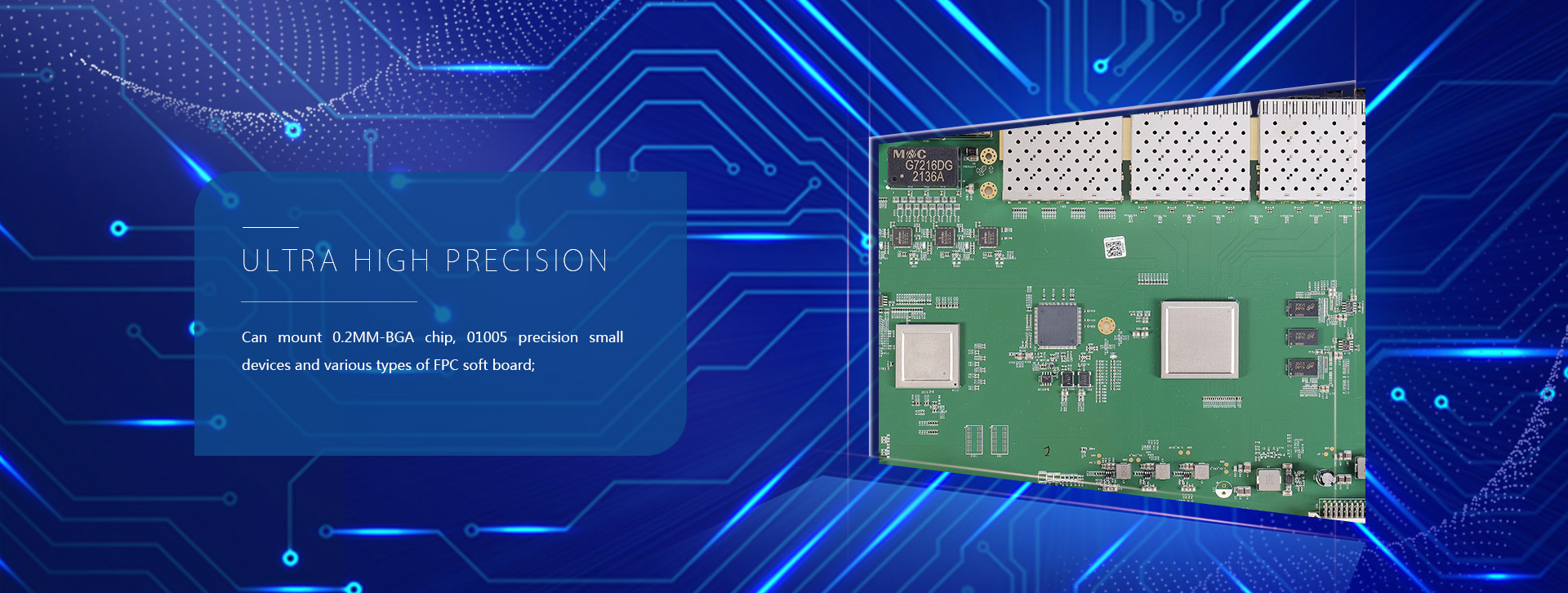

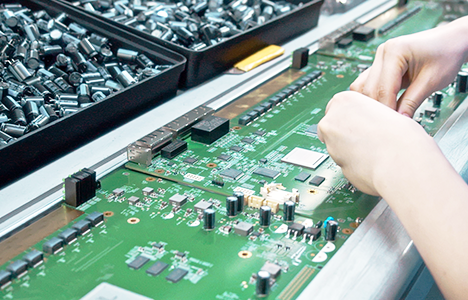

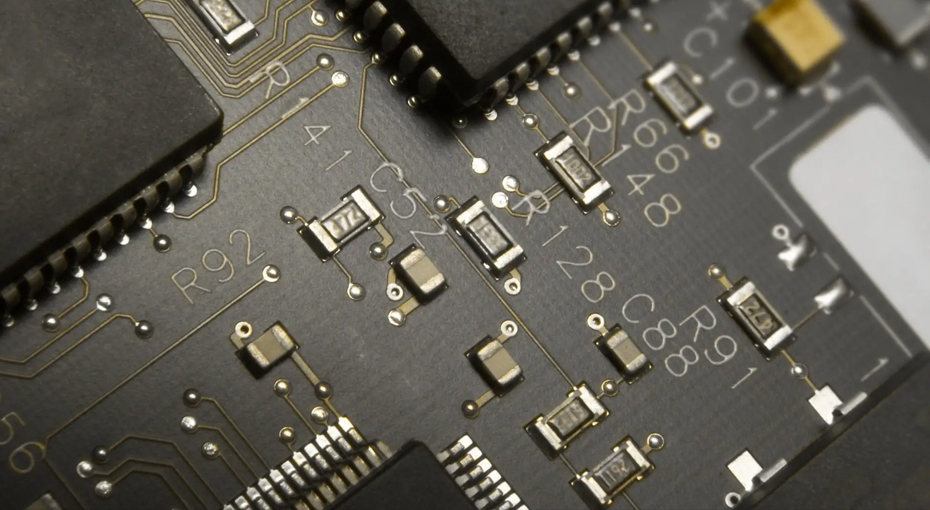

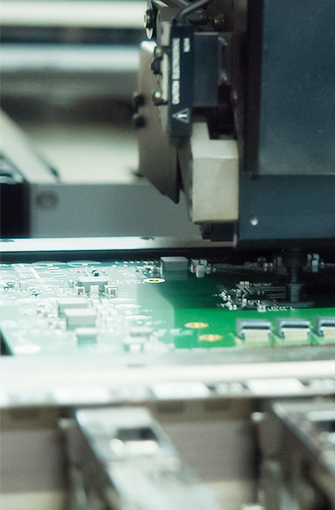

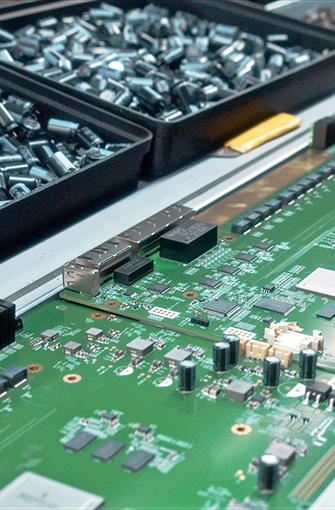

SMT and DIP processing

Undertake SMT patch and DIP plug-in processing, including sample trial production and batch product production, good at difficult SMT patch processing.

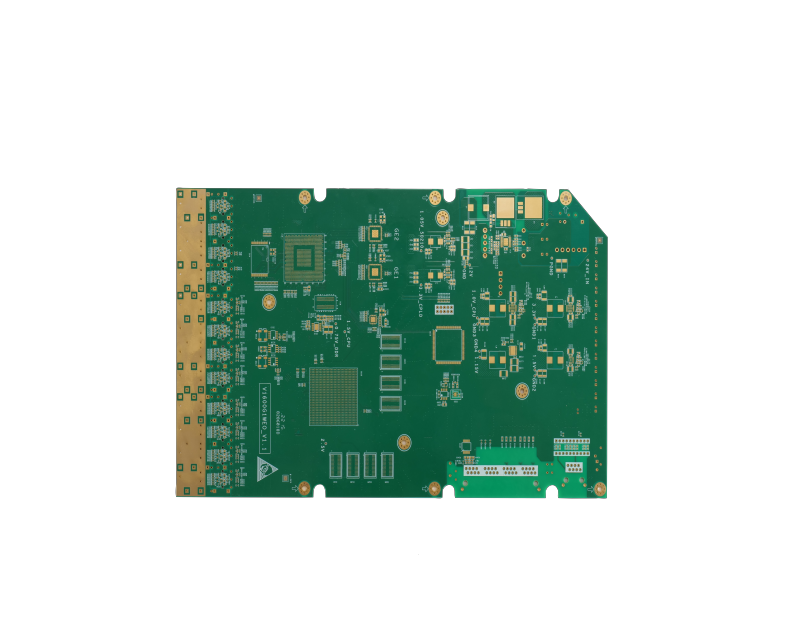

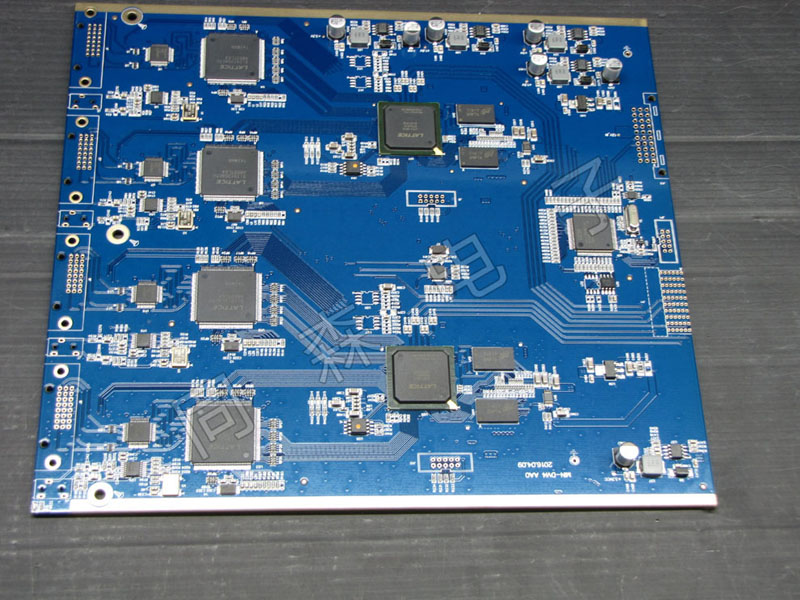

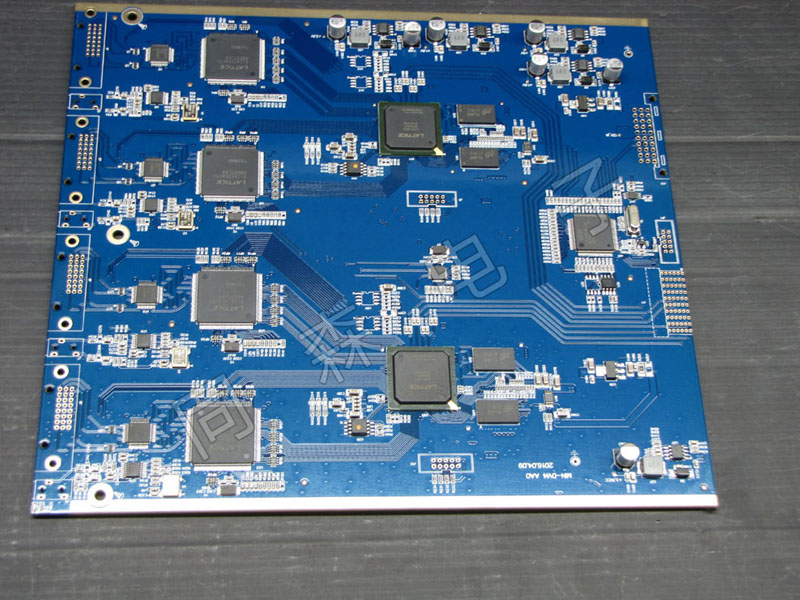

PCB board

High-precision PCB production, 2-68 layers, minimum line width and line spacing 3/3mil, minimum via 0.1mm. The raw materials of large factories are used, and all kinds of certifications are complete.

Finished product assembly test

Standard assembly cable, SOP standard operation, all kinds of testing instruments are complete, equipped with high temperature aging room, which can complete the assembly test of various electronic products.

SOLUTION

BUSINESS PROMOTION

-

Tongsen business license

Tongsen business license -

Xinpin ISO Chinese certificate

Xinpin ISO Chinese certificate -

Xinpin ISO English certificate

Xinpin ISO English certificate -

High-tech product certificate-PCBA integrated circuit board

High-tech product certificate-PCBA integrated circuit board -

High-tech product certificate - efficient PCBA board patch processing service

High-tech product certificate - efficient PCBA board patch processing service -

Tongsen patent certificate

Tongsen patent certificate -

Tongsen Patent Certificate II

Tongsen Patent Certificate II -

Tongsen patent certificate three

Tongsen patent certificate three

ABOUT TONGSENG

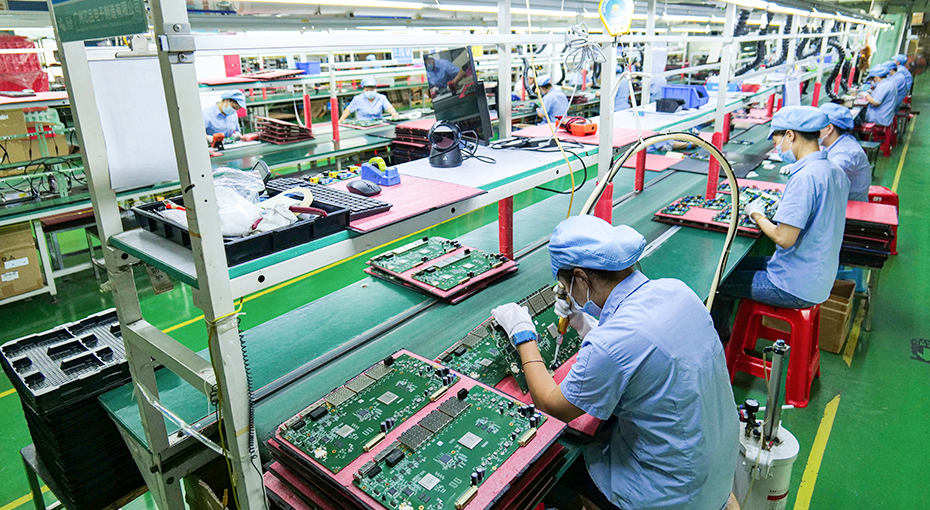

Guangzhou Tongsen Electronic Technology Co., Ltd. (Guangzhou Xinpin Electronics Manufacturing Co., Ltd.) is a high-tech enterprise established in 2008 with a paid-in registered capital of 10 million RMB.It is located in Guangzhou Science City, the largest high-tech zone in Guangzhou, with a plant area of nearly 5,000 square meters and nearly 200 employees. It is equipped with six new Fuji NXT-3SMT SMT production lines, three DIP plug-in production lines, two assembly lines and high temperature aging room. We have also been certified by IATF16949, ISO9001, UL, CCC, SGS, ROSH and other related certifications. The business areas cover industrial control, military industry, automotive electronics, electric power, medical treatment, Internet of Things, robotics, communication modules, security protection, cloud computing, instrumentation, etc. We are working with more than 200 long-term and stable partners, including Chinese Academy of Sciences, Amphenol and other well-known domestic and foreign companies, and more than ten A-share listed companies such as Infore Environment, Royal Silver, Baiyun Electric, and Higer Communications.

-

Company front desk

Company front desk -

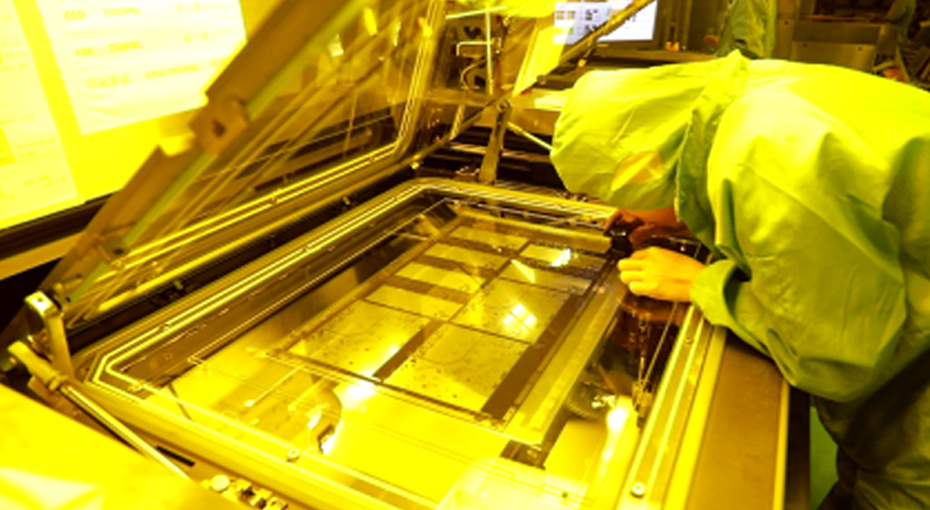

SMT workshop

SMT workshop -

SMT workshop

SMT workshop -

SMT workshop

SMT workshop

-

2008

YearBorn great

-

5000

m²Plant area

-

200

人Number Of Workers

-

20

millionSMT processing capacity

关于同森電(diàn)子

ABOUT US

2008年成立,高新(xīn)企业,实缴注册资本1000万,位于广州最大的高新(xīn)區(qū)广州科(kē)學(xué)城内,厂房面积近5000平米,员工近二百人,拥有(yǒu)六条全新(xīn)富士NXT-3SMT贴片生产線(xiàn),三条DIP插件生产線(xiàn),二条装配拉線(xiàn)及高温老化房。具备IATF16949,ISO9001,UL,CCC,SGS,ROSH等相关认证。业務(wù)领域涵盖工业控制、军工、汽車(chē)電(diàn)子、電(diàn)力、医疗、物(wù)联网、机器人、通讯模块、安全防护、云计算、仪器仪表等。長(cháng)期稳定服務(wù)的客户超过二百家,其中包括中科(kē)院,安费诺等國(guó)内外知名企业,以及盈峰环境、御银股份、白云電(diàn)器、海格通信等超过十家A股上市公司。

-

2008

年公司成立于

-

5000

㎡占地面积

-

200

+员工总数已达

-

2000

万SMT贴片加工日产能(néng)

NEWS INFORMATION

-

What are the common steps of SMT chip processing? 2022-07-21

SMT in SMT chip processing, also known as surface mounting technology or surface mounting technology, is the abbreviation of Surface Mounted Technology, and it is also a popular processing technology in the electronic processing industry. SMT chip processing is to process on the basis of PCB circuit board, and install components on the PCB. The following briefly introduces the common steps of SMT chip processing. Understand more - What should we pay attention to in patch processing? 2022-07-21

- What are the electrostatic protections in the SMT process? 2022-07-21

- What are the production links of pcba processing? 2022-07-21

-

What should be paid attention to in SMT chip processing and production 2022-08-22

The SMT chip processing production process must have a strict standardized process to avoid errors in the process of high-frequency line replacement and material replacement. In addition, during the processing, the placement machine equipment must also be checked regularly. 了解更多(duō) - Reasons for Preheating Before PCBA Processing 2022-08-22

- What is the accuracy of SMT patch and how to improve patch efficiency? 2022-08-22

- What are the common steps of SMT chip processing? 2022-07-21

Common Problem

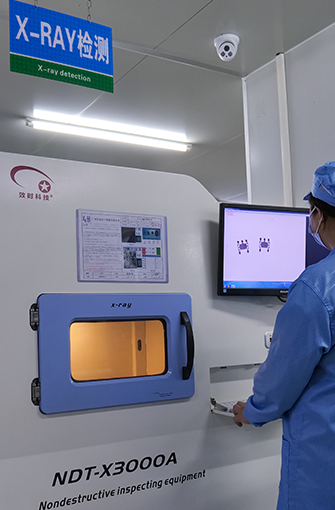

How to detect counterfeit electronic components during Pcba processing?

Counterfeit electronic components pose a huge risk to industries around the world. These counterfeit parts affect nearly every industry, including medical, automotive, consumer goods, networking, communications, aerospace and defense.

During the Pcba processing , these components may be overlooked, which will increase the failure, scrap and rework rate involving the pcba circuit board. It has an impact on the overall profitability and value-at-risk of smt chip processors, and has serious consequences in high-reliability applications, especially in the medical and automotive industries. Therefore, it is critical that these components pass some industry-specific tests to identify counterfeit electronic components before smt processing, DIP insertion. Both manufacturers and suppliers have published many specifications and guidelines to establish and maintain product traceability. As long as these practices are adhered to, the use of counterfeit electronic components can be eliminated in the production process, ensuring that the products are authentic electronic components. Tongsen Electronics guarantees that it does not purchase counterfeit components, does not use counterfeit components, and does not recommend the three principles of unknown channels.

What are counterfeit electronic components?

Counterfeit electronic components are counterfeit, non-genuine parts that have been misrepresented in their origin or quality. Counterfeiting involves passing low-quality parts as high-quality parts by changing part numbers, repackaging, or mixing with better-quality parts.

Typical counterfeit electronic components:

1. Unapproved source.

2. Manufactured by an unauthorized contractor not OCM (Original Component Manufacturer).

3. Violation of the original OCM design, model and performance specifications.

4. Whether substandard items are sold as new products.

5. There are incorrect files.

Introduction of smt processing and production process

1. What is smt processing and production?

Smt processing production, also known as surface assembly technology (SUrfaceMountechnology for short SMT), is a new generation of electronic assembly technology developed from hybrid integrated circuit technology. It is characterized by the use of component surface mount technology and reflow soldering technology. Next-generation assembly technology. The main equipment of smt production line are: printing machine, placement machine (electronic components on the upper surface), reflow soldering, plug-in, wave furnace, test packaging. The wide application of SMT has promoted the miniaturization and multi-functionalization of electronic products, and provided conditions for mass production and low defect rate. smt is surface assembly technology, which is a new generation of electronic assembly technology developed from hybrid integrated circuit technology.

2. Process flow of smt processing and production

machine).

2. Dispensing: It is to drip the glue into the fixed position of the PCB, and its main function is to fix the components on the PCB. The equipment used is a glue dispenser, which is located at the front end of the smt production line or at the back of the inspection equipment.

3. Mounting: Its function is to precisely mount the surface mount components to the fixed position of the PCB. The equipment is a pick and place machine, which is located behind the screen printing machine in the smt production line.

4. Curing: Its function is to melt the patch glue, so that the surface-mounted components can be firmly adhered to the PCB board. The equipment used is a curing oven, which is located behind the placement machine in the smt production line.

5. Reflow soldering: Its function is to melt the solder paste to make the surface mount components stick to the PCB board. The equipment used is a reflow oven, located behind the placement machine in the smt line.

6. Cleaning: Its function is to remove the welding residues such as flux that are harmful to the human body on the assembled PCB board. The equipment used is a washing machine, the location is not fixed, it can be online or not.

How to judge the pcba processing factory is reliable?

Many customers are often confused when looking for a PCBA processing factory . They do not know how to choose a high-quality, safe and secure processing factory. The circuit board assembly production process is very complicated. From the initial conversation between the two parties to the procurement of components, to SMT processing, it is easy to have problems in some links, resulting in unsatisfactory production results. So how do we choose a reliable pcba processing factory for cooperation?

1. Look at the basic production equipment: high-quality factories must have professional production equipment, and manufacturers need very professional equipment when producing. At this time, it is necessary to see whether the equipment is complete, whether it can complete all the processing procedures independently, whether it fully adopts automatic equipment, and whether the machine production process can meet your product requirements, etc., such as high-speed placement machine, multi-temperature zone Reflow soldering, AOI tester, ICT online tester, automatic printing machine, etc. These are the basis of production.

2. Enterprise environment: The environmental sanitation of the factory can directly reflect the production quality of the factory. There is no direct relationship between the production environment of the factory and the production results, but the better the production environment, the higher the requirements of the factory for the process, and only the details are done. The most meticulous people will focus more on serving customers and making their products well.

3. Product quotation: The price of smt patch proofing is relatively transparent in the industry, some are too high, some are very low, all kinds of mess. Like Tongsen Electronics chooses to purchase original parts from formal channels and strictly controls product quality. Although the processing cost is increased, the product quality can be guaranteed. However, some pcba processing manufacturers may choose to cut corners and use fake raw materials to reduce prices, so that the quality is unstable. We should choose the most cost-effective manufacturer according to our own situation, and don't choose a small workshop without quality assurance because of cheapness.

4. Service: As the brain of intelligent products, PCBA circuit board is not only required to be manufactured. As a qualified supplier, pre-sales and after-sales work should also be paid attention to. A trustworthy factory with a good sense of service can solve many unnecessary troubles for customers in the manufacturing process, provide reliable after-sales support, and respond quickly to customers, thus ensuring the smooth progress of production. We can choose a more suitable supplier by understanding the company's corporate culture and the factory's attitude towards customers.

(Telephone contact)

OEM:136-3210-0256

Processing:150-1879-2052

E-mial:810052158@qq.com

Address: 4th Floor, Building J, Jitang Industrial Park, No. 8, South Yunwu Road, Science City, Huangpu District, Guangzhou